A&E like automation and development or sales and efficiency. A&E Produktionstechnik GmbH from Dresden offers both. The Saxon company has been developing, producing and selling flexible injection solutions for single, multi-component and vertical injection moulding machines since 2002. The main focus of the development work is on increasing the efficiency and the cost-saving flexibility of single, multi-component and vertical injection moulding machines. One of the company’s most innovative technologies is the A&E sandwich panels. They enable plastics processors to convert their injection moulding machines inexpensively to the sandwich injection molding process and thus, for example, comply with the legal requirements of the EU and the federal government through the use of recyclates. The advantage: You don’t have to deal with the classic problems that arise with the legally required reuse of old plastics, e.g. the deterioration in properties through the use of old plastics. In the sandwich injection moulding process, secondary raw materials, i. e. plastics that have already been disposed of at least once are used to manufacture new products – in this case moulded parts made of plastic. Here, the old plastics are “hidden” inside the moulded part without the properties of the moulded part being impaired by the old plastic. The prerequisite is that specialists support the processing of recyclates using the sandwich method. The sandwich process is not limited to this application. For example, it is also possible to foam the core material – ideal for lightweight construction applications.

Efficient use

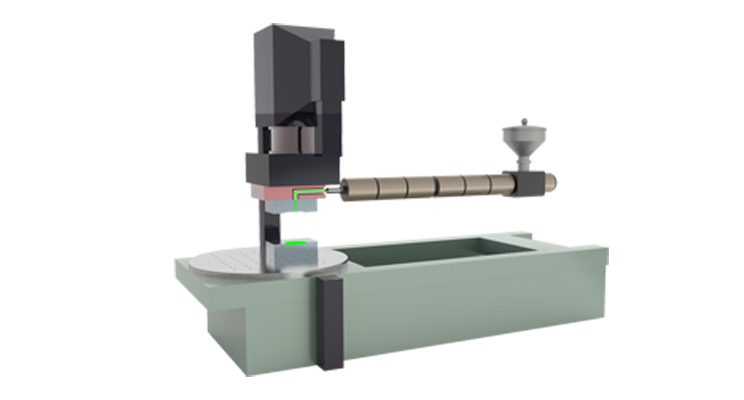

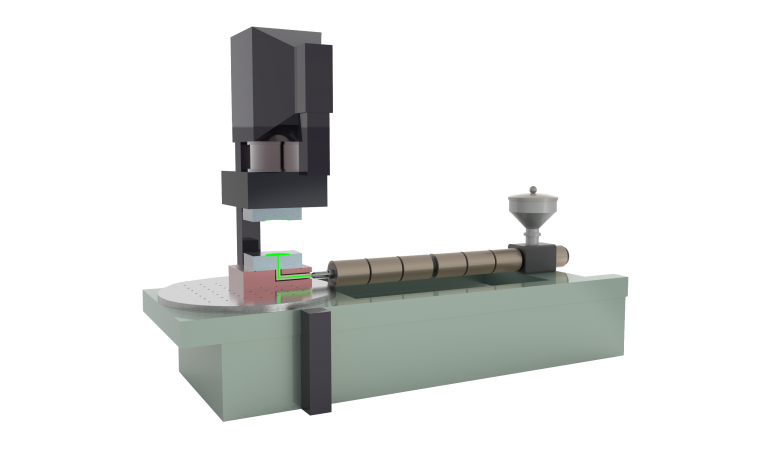

The hot runner sandwich plates from A&E offer more efficiency and / or flexibility when using injection moulding machines. The principle is simple. Hot runners in intermediate plates connect the nozzles of the injection units with the mould sprue bushes if their positions are different. Due to the safe, adjustable, non-positive connection of the tool sprue bushing to the hot runner nozzle, the highest level of leakage security is offered. The hot runners are slidably mounted in the intermediate plates in order to achieve different positions of the tool sprue bushes in relation to the clamping surface. The contact force between the hot runner nozzle and the mould sprue bushing is generated via an adjusting device. The contact force to the tool sprue bushing is steplessly adjustable independently of the machine and can act permanently or cyclically.

The advantages are obvious: By using the hot runner intermediate plates, no machine and / or mould conversion is necessary if the positions / positions of the nozzles of the injection units do not match those of the moulds.

The hot runner plates can be assembled and disassembled just as easily as with conventional tool installation and removal. If service is required, the hot runner can simply be dismantled from the steel plate and serviced. This reduces downtimes and costs, even if the tool is changed frequently, and increases service life. In addition, sensors, e.g. to monitor the nozzle contact force, and the injection moulding machine can be expanded to include additional special injection moulding processes.

The adaptation to the customer machine and the production of the hot runner sandwich plates from A&E are made to order. They are therefore suitable for 1K, 2K and also for vertical machines

A team of competent engineers works out economical solutions for your machine, tool and process adjustments and also puts them into operation on your machines. A&E stands for applications and developments for plastics processing and has proven high quality in production, reliability and innovation for almost two decades. More efficiency and higher sales with the technologies from Saxony.