Hot runners in intermediate plates connect the nozzles of the injection units with the tool injection bushings if their positions are different. The hot runners are slidably mounted in the intermediate plates in order to achieve different positions of the tool injection bushings in relation to the clamping surface. The contact force of the hot runner nozzle to the mould injection bushing is generated via a setting device. The contact force to the tool mould sprue bushing is infinitely adjustable independently of the machine and can be permanent or cyclical. The hot runner intermediate plates are manufactured with threaded holes according to EUROMAP2 or T-slots. Exchangeable nozzles and injection bushings for the hot runners, the cooling of the steel plate and a heat insulation plate are included in the standard equipment.

Further options on request.

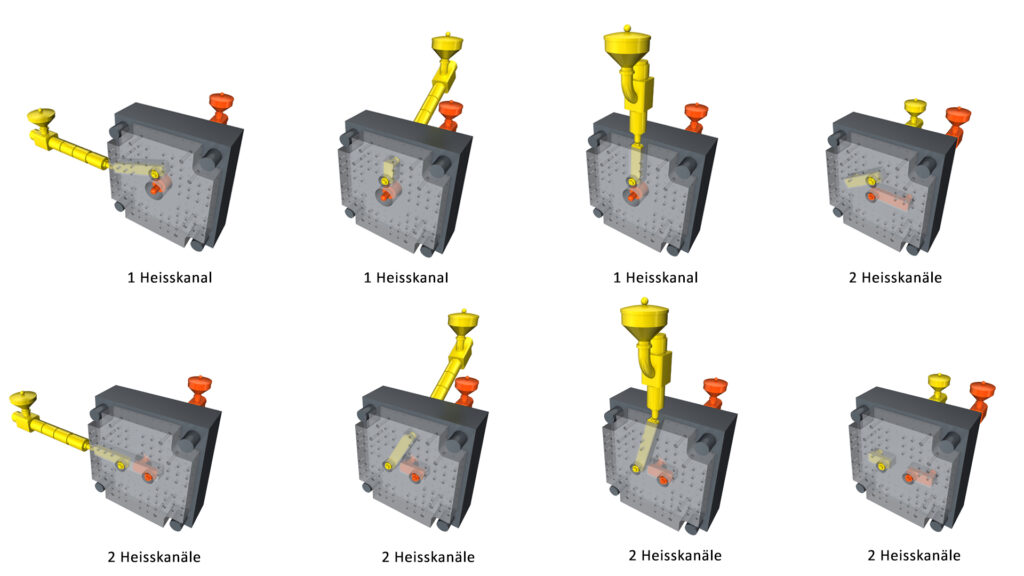

Basic principle of selected examples

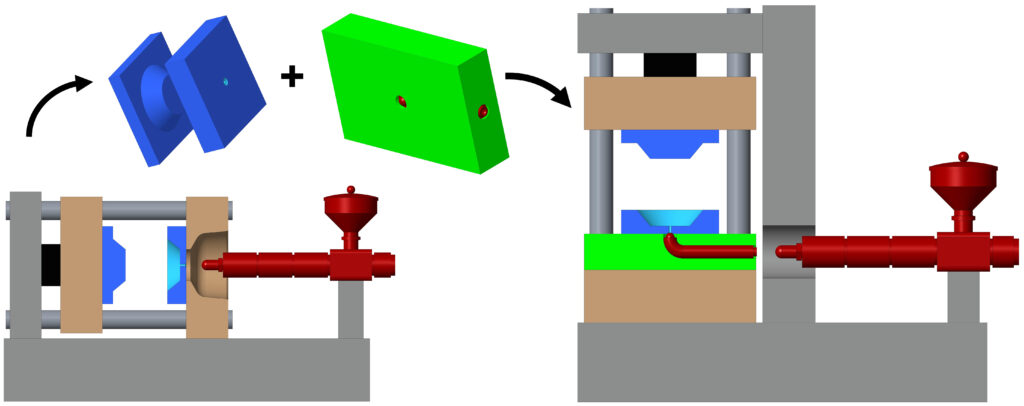

Hot runner intermediate plates in vertical machines enable the installation of tools from horizontal machines

Examples of A&E hot runner plates

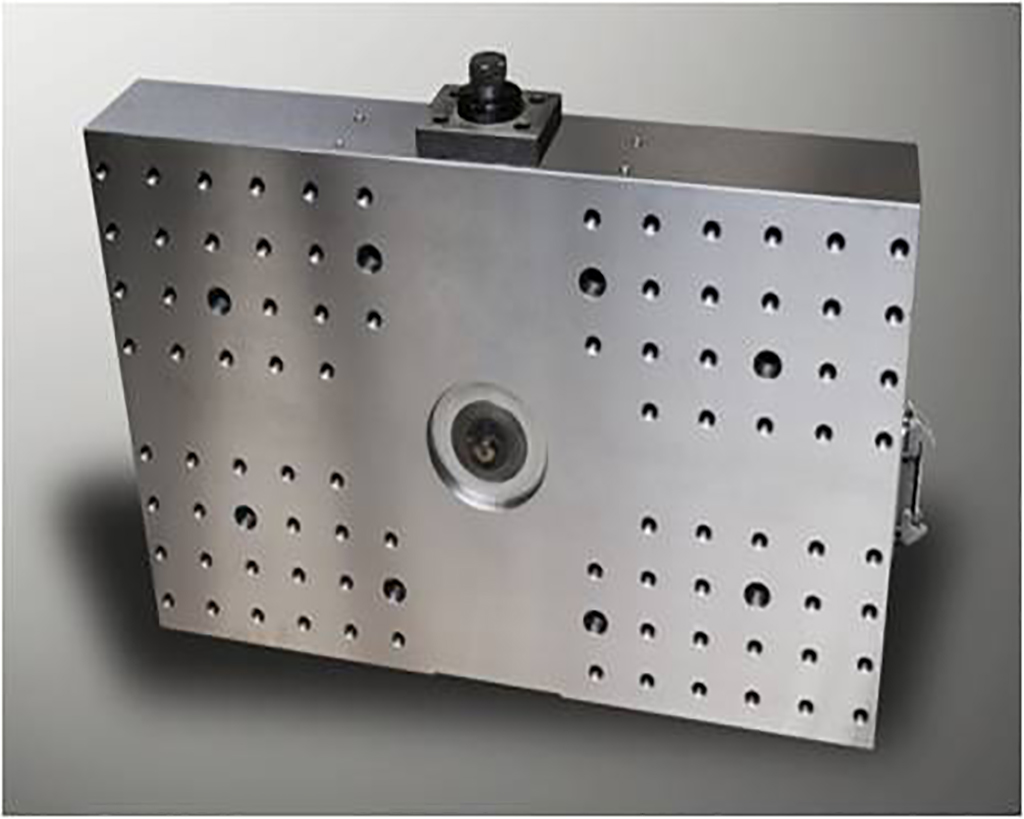

Hot runner adapter plate for installation in vertical injection moulding machines

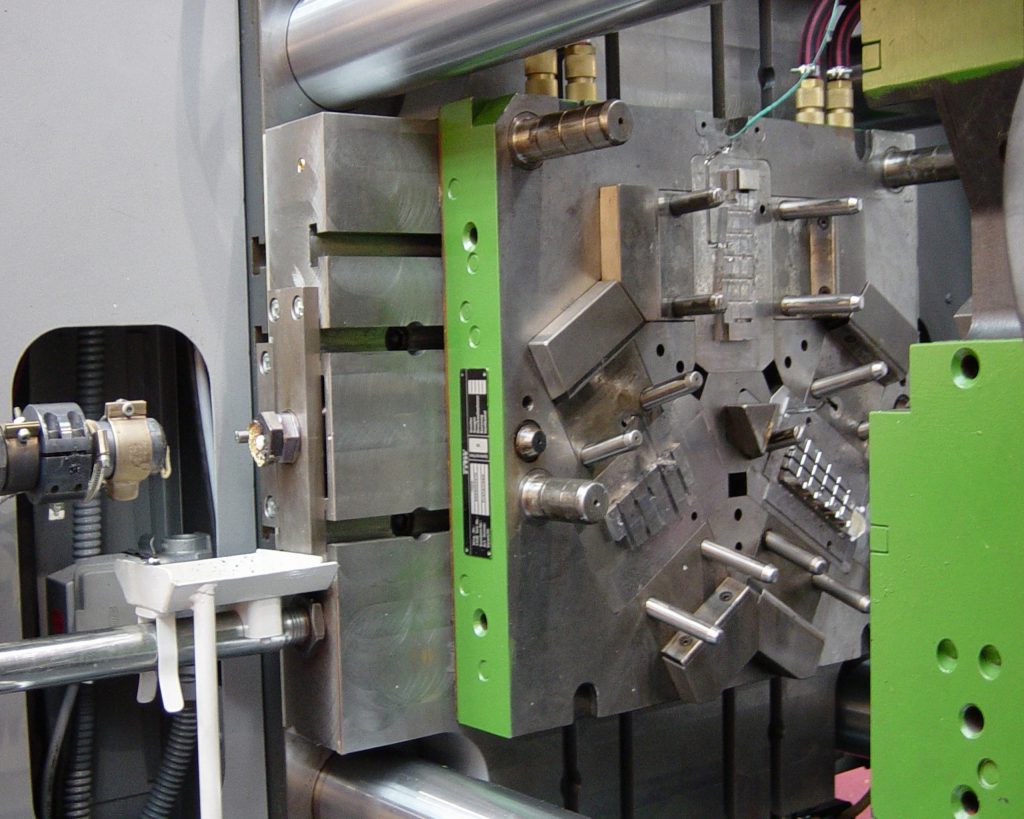

2K hot runner intermediate plate

Hot runner adapter plate on a movable sliding table