The 2K sandwich units can – depending on the application and customer requirements –

- be built in a steel intermediate plate

or - directly in the muold half on the nozzle side, referred to as the “hot half”

or - be attached directly to the injection units, referred to as “nozzle or cylinder head”.

The 2K sandwich units are available for all commercially available multi-component injection moulding machines in all sizes and designs and for machines from all manufacturers. They can be used in new machines as well as in machines that are already used in production.

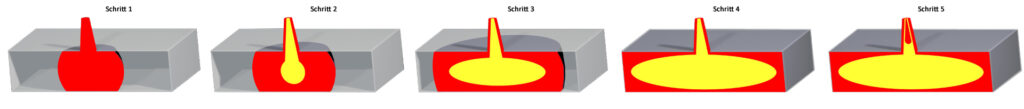

Principle graphics – sandwich

* Due to the poor thermal conductivity of thermoplastics compared to metals, the injected melt only solidifies directly on the wall of the cavity, but continues to flow. The cavity is thus filled in that the melt has to flow through already solidified thermoplastic from the injection point to the end of the flow path.