Caption: A&E sandwich panel

In future, plastics processors will have to use a proportion of old plastics (recyclates = regrind, re-granulates) for or in their plastic products. These are legal requirements of the EU and the federal government. A large number of measures are required in order to be able to meet these requirements. There are several technologies for reusing and recycling old plastics:

- mechanical recycling, i. e. melt thermoplastics again and process them into new products using injection moulding and / or extrusion

- chemical recycling, i. e. old plastics are broken down into their components (molecular chains) using chemical processes. There is a separation of “foreign components”. The molecular chains are then transformed into new plastics in further chemical processes.

- thermal recycling, i. e. incineration, use of the heat of combustion. This technology is no longer practicable in view of climate change, as CO2 is also produced when it is burned.

Of course, it is possible to shred the old moulded parts, melt them again and immediately manufacture new moulded parts using injection moulding. This is also done on a large scale and is state of the art, but this is not so easy with all old plastics. Old plastics are mostly dirty and often consist of several different plastics. In addition, certain properties (mechanical strength values) deteriorate as a result of reprocessing.

Collecting used plastics is also problematic in plastics recycling. In order to be able to use old plastics economically, they must:

- be pure,

- free of impurities and foreign bodies (stones, glass, ceramics …),

- be safely available in sufficient quantities,

- do not have poorer properties to a large extent as a result of reprocessing.

However, the conventional waste plastics add up to millions of tons of different plastics. Various old plastics cannot be processed directly into new parts

Sandwich process: economical processing of old plastics

The sandwich process (coinjection / coinjection) offers a solution for the processing of old plastics – sandwich injection moulding, which is used for the production of moulded parts made of plastic. In the sandwich process, the old plastics are “hidden” inside the moulded part without the properties of the moulded part being impaired by the old plastic. Processing old plastics in this way is therefore one of the options for mechanical recycling.

The hot and liquid plastic is injected into a temperature-controlled mould, where it cools down and hardens. The injection moulding of thermoplastics is based on the swelling flow effect: The plastic melt flows in the mould cavity (mold-forming cavity) from the injection point to the end of the flow path through already solidified melt. This forms the surface of the moulded part (“skin”). If during the injection – while the mould is being filled – a different melt type is used, e.g. it is injected melt from recycled material, this remains in the core of the molded part, surrounded by a “skin” of e. g. new plastic.

Depending on the geometry of the moulded part and the thermoplastic types used, the process enables up to 60% of the core material, for example recycled / old plastics, to be injected into the interior of the moulded parts. The old plastic is then no longer visible (see Fig. 1 red) and the properties of these parts do not differ from those that are injection-moulded from 100% new material. Nature has a good example for this. The bones of birds, for example, consist of a compact surface (skin), but are largely hollow inside. Nature practically practiced “lightweight construction” here. The weight is reduced, unnecessary material is omitted. The mechanical loads are only transmitted through the compact skin, not through the inside. In sandwich injection molding, “superfluous” material is replaced by the old plastics.

Economical and environmentally friendly plastic with the sandwich process

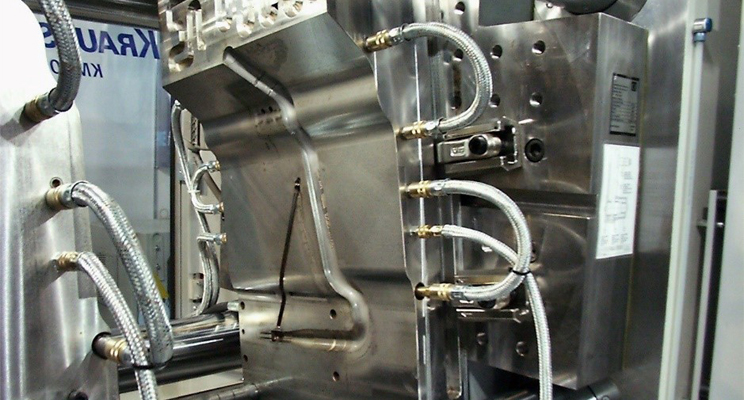

By using old plastics, sandwich injection moulding offers an economic advantage: Recyclates are not as expensive as new material. That benefits the company. Another major advantage is the environmental aspect. In this way, old plastics are put to a new use and the environmental impact is reduced. The application of the process is not limited to new molded parts. Moulded parts that have already been produced can also be converted to production using this process. The prerequisites for sandwich injection moulding are machine and process know-how, two-component injection moulding machines and cold runner bar casting tools.

The best solution from an expert hand

A&E Produktionstechnik GmbH has been offering the corresponding nozzle technology and process know-how for both new machines and machines that are already in production. 2K sandwich units that are installed in different “housings” are part of this product family. 2K sandwich unit stands for two-component sandwich nozzles or valves with which the sandwich injection moulding process (coinjection) can be carried out on multi-component injection moulding machines. Our team of competent engineers works out economical solutions for your machine, tool and process adjustments and also puts them into operation on your machines. A&E stands for applications and developments for plastics processing and has proven high quality in production, reliability and innovation for almost two decades.