Innovative A&E technology for KraussMaffei project at Fakuma 2024

Sandwich technology as the key to precision, efficiency and sustainability

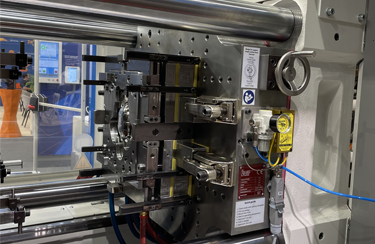

As part of KraussMaffei’s ‘Turtle Project’, A&E Produktionstechnik GmbH developed the sandwich plate, which was presented for the first time at this year’s Fakuma (15–19 October 2024, Friedrichshafen).

This innovation makes the fully electric PXZ 121 Multinject injection moulding machine even more flexible: Thanks to the sandwich plate manufactured by A&E, the system can also be used for the sandwich process (coinjection) without any additional effort. The melt flows from the two injection units are combined sequentially and/or simultaneously in the sandwich plate, enabling the production of moulded parts with a skin-core structure.

“The sandwich plate we have developed increases the flexibility of the machine and expands its functions through the use of the sandwich process. Thanks to the sandwich plate, it is no longer necessary to modify the machine or change tools in order to use the sandwich process. After removing the sandwich plate, the machine can still be used for multi-component injection moulding (overmoulding),” emphasises Volker Reichert, Managing Director of A&E Produktionstechnik.

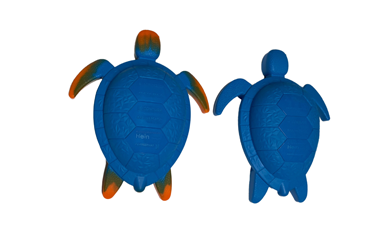

The core material of the ‘turtle’ moulded part to be produced at Fakuma consists of mechanically recycled PC/ABS E-LOOP 5120MR from ELIX Polymers. However, a foamed core made from recycled material is also conceivable and offers further potential for lightweight construction applications and sustainable production. The visible, high-quality outer skin is made of chemically recycled and reprocessed ABS E-LOOP P2H-AT CR, which is available in various colours, according to Krauss Maffei.

The combination of innovative machine technology, sustainable materials and sandwich panels impressively demonstrates the potential of modern plastics processing for resource conservation and the circular economy.

With the development of this key component, A&E Produktionstechnik underscores its expertise as a reliable partner for customised solutions in the field of injection moulding technology and at the same time sets an example for sustainable innovations ‘Made in Germany’.